Industry

Parcel

Application

Package sortation

Product

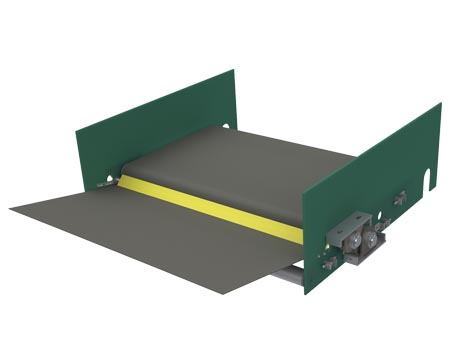

Flexco Hitch Guard

Objective

Reduce downtime from belt damage

Eliminate package damage

Reduce foreign object debris on belt

Conveyor Detail

Solid woven PVC belt

Problem:

A large package delivery operation developed a homemade solution to combat the gap left in one of their hitch conveyors. In order to keep envelopes and small package parcel bags from getting sucked into the bend pulley of the waterfall hitch, the maintenance team placed a block of UHMW in the gap, with a few stops attached to the side panels of the conveyor. While that stopped many of the packages from being sucked in and damaged, it did not stop the shipping bags, envelopes, and other foreign object debris (FOD) from becoming jammed in between the UHMW block and the belt, oftentimes causing damage to the package or envelope, as well as the conveyor belt.

Solution:

The homemade solution, while solving one problem, was creating a new catch point for FOD on the belt. Once a package was broken or ripped open, one of two things could happen: the FOD might get caught in the homemade hitch protector and jam, acting as a knife and slicing the belt; or, in the case of an open hitch, the FOD could get sucked into the bend pulley and get pulled around the transfer, causing the belt splice to fail and a hole to form. When the maintenance team was presented with the Flexco Hitch Guard, they were impressed with its precise fit in the hitch, the segmented design of the guard, and the bright yellow color that makes it easy to see against the black belting.

Result:

Once the Flexco Hitch Guards were installed, anyone who was not a believer had a change of heart. Not only were packages gliding effortlessly over the hitch, but shipping bags and envelopes were not getting caught in the hitch because of the tight seal of the guard to the belt. If a package or FOD did get stuck, one of the Hitch Guard’s segments dislodged to prevent damage to the belt and protect the product that was being conveyed. A visual check by the maintenance team quickly indicated if a segment was gone thanks to the bright yellow color. Instead of a whole hitch protector being dislodged, only a small part of the hitch protection was gone, allowing packages flowing over the hitch to still make a smooth transition until maintenance could quickly snap a replacement segment back into place.