Industry

Hard Rock Mining

Application

Conveying run-of-mine iron ore

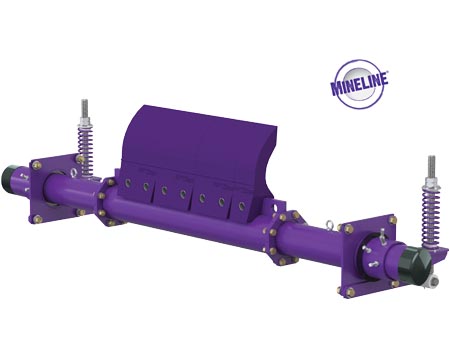

Product

MXP Extreme Duty Precleaner

Objective

Reduce carryback

Reduce maintenance time

Conveyor Detail

60" wide, 1.19" thick steel cable belt, running at 400 fpm at 2000 PIW, with a 75" head pulley diameter

Problem:

A hard rock mining company in the Midwest had tried various cleaners over the years, finding the product quality and service to be lacking. Because of the high pressures involved in the application, other cleaners would become overwhelmed and break and they found themselves cleaning the conveyor galley way too often. In fact, they considered Thursday to be their “downtime day” and dedicated the whole shift and crew to wash down the carryback.

Solution:

When the operation was approached by Flexco to operate as a test site for the MXP Extreme Duty Precleaner, they jumped at the chance. The team worked with Flexco to properly specify the cleaners and mount them to the structures correctly, and were provided with a level a service not previously offered by other manufacturers.

Result:

The results were astonishing, with several members of the maintenance team commenting that they had never seen a cleaner work so well. Their “downtime day” is now spent doing preventative maintenance to help their conveyor run more smoothly because they do not need to clean under the conveyor nearly as often as they had in the past. Not having to work around the conveyor as often also makes for a safer work environment for the miners. The mine is now running more safely and efficiently than ever.