Belt Rating and Tension. Belt Thickness. Pulley Diameter. All three of these measurements are important when choosing the correct conveyor belt fastener for your application. But there is at least one more factor that we feel is important in your decisions – so important, in fact, that we wrote a blog about it. Metal selection.

How serious are we about metal selection? Serious enough to take a deep dive into the wear rate of our metal offering in order to see how they compared. Specifically, we wanted to know how Flexco’s proprietary metal, MegAlloy®, did in wear testing when compared to steel and stainless steel. This information would allow us to give customers an expected average wear life for all our steel products and give customers a reason to choose MegAlloy for their most abrasive applications. But before we get to testing, it’s important to know what MegAlloy is and how it is used.

What is MegAlloy®?

|

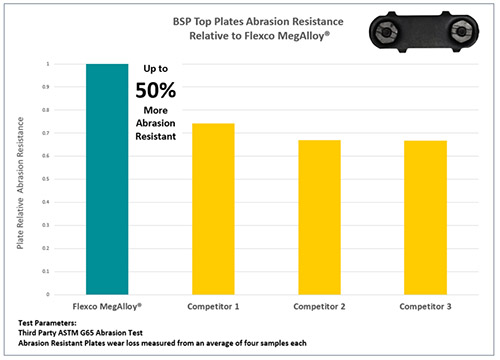

| MegAlloy® belt fasteners out-performed the competition, boasting 50% more wear life.

|

MegAlloy contains a proprietary blend of heat-treated steel that extends the life of splices on conveyor belts in abrasive environments. It can be used anywhere abrasive materials are present, including: aggregate, granite, limestone, bagging cement, sand and gravel, shingles, foundries, iron ore, and metal and concrete recycling.

Of course, there are also some applications where Flexco doesn’t recommend using MegAlloy, including: corrosive environments, like citrus and phosphate; impact areas, like under crushers and load zones; and on hot belts where the belts wear out faster than the actual fasteners. In those instances, Flexco recommends using steel or stainless steel, depending on the application.

How the conveyor belt fastener testing was conducted

Now that you are up-to-date on MegAlloy and where it should and shouldn’t be used, let’s get back to the testing. We arranged for the ASTM G65 Abrasion Test to be conducted at a third-party testing facility using a standardized test setup and equipment and the Flexco® Bolt Solid Plate Fastening System. In this particular test, fasteners are first weighed. Then an abrasive disc is run against the fasteners for a set amount of revolutions and the weight loss of the fasteners is measured after testing is complete.

During this particular test, the abrasion resistance was measured using an average of four samples from each type of metal. As the test progressed, we brought in equivalent fastener metal options from three Flexco competitors to get an idea of how MegAlloy performed against them as well.

The results are in …

The results of the third-party ASTM G65 Abrasion Test was not a shock to those of us who have been out in the field and seen our MegAlloy fasteners working in some of the most abrasive environments known to man. But having the numbers to back up our observations was certainly helpful.

MegAlloy performed 50% better than the competition.

That’s 50% better than steel, 50% better than stainless steel, and 50% better than our three competitors. In short, you can get an average of 50% more wear life out of MegAlloy fasteners in an abrasive environment when you choose the right fastener for the application.

Why and how Flexco tests belt conveyor system products

Flexco conducts tests like these to ensure that we are producing the best products for our customers – to keep their belt conveyors running at maximum efficiency with limited downtime. We test new products to make sure they meet or exceed the quality standards we have set for our fasteners, and continued product testing ensures that our offerings are still top notch.

We start our testing on our internal conveyors, measuring fastener strength and splice life versus our leading competitors. We then validate those results in the field and at third party vendors if applicable. We also work closely with leading conveyor belt manufacturers in order to stay abreast of the newest technologies and advancements in the industries we serve.

We also test for mechanical fastener static tensile strength and even hinge pin fatigue to ensure that our fastening systems as a whole are performing at the highest levels.

But testing doesn’t stop at fasteners here at Flexco. We’re testing the endurance of our installation tools, the wear of our cleaner blades, the strength of our belt clamps, and more. We have test rigs and testing stations located across the globe that perform thousands of tests a year to ensure operational efficiency, maximum productivity, and employee safety.

Specifying MegAlloy® for your mechanical belt fastener application

If you’re looking to install fasteners that bring 50% more wear life to your abrasive application, MegAlloy is available as a metal option in several of Flexco’s fastening systems. Check out our Mechanical Belt Fastening Systems page to see if your chosen fastener is available in MegAlloy.

See how switching from steel to MegAlloy reduced downtime and saved money for an aggregate quarry in this real-life result.

Not sure what kind of fastener or metal would be best for your application? Sign up for a free assessment and a local representative will come out to your operation and help you choose the right fastener for your belt.

Authored by: Russ Heintz, Training and Technical Specialist

Russ Heintz has been with Flexco since 1995, working in various roles within the company before becoming Training and Technical Specialist. In this role, Heintz focuses on the efficiency of our products through in-house and field testing. Heintz also regularly conducts classroom and hands-on, internal or on-site training with Flexco employees, distributors, and customers.